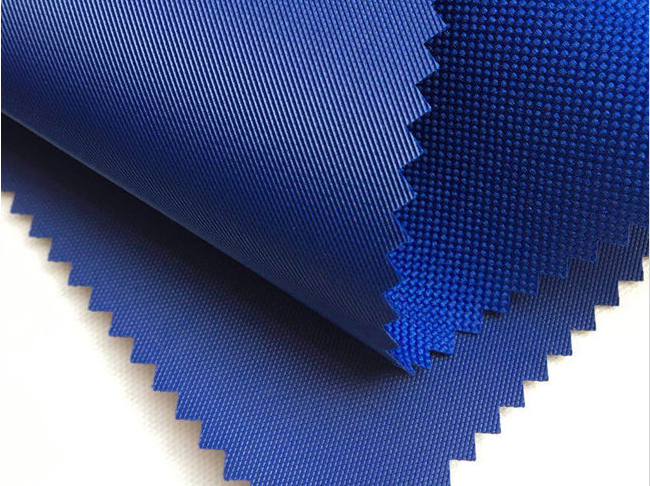

The coated Oxford cloth is mainly coated with a layer of material on the basis of the cloth, which adds a special function to the cloth. This article introduces several classifications of Oxford cloth coating for readers to use.

PA coating

PA coating is a widely used dry coating method, and the main component of the coating agent is polyacrylate (Polyacrylate) colloid, referred to as PA, also known as AC. This coating can make Oxford cloth windproof and sagging at the same time.

PU coating

PU coating, that is, polyurethane coating, makes the fabric feel plump, elastic, and film-like on the surface.

Heavy coating

The heavy coating is used for preventing down from running down after coating, so it is suitable to be used as down jacket fabric. But now the coating where there is a water pressure requirement of the PA coating is also called heavy coating.

PA white glue coating

It is a layer of white acrylic resin on the surface of the fabric. This coating can increase the coverage of the fabric, not through the color, and make the color of the fabric more vivid.

PU white glue coating

A layer of white polyurethane resin is coated on the fabric surface, so-called the PU white glue coating. This layer has the same function as PA white glue. However, the fabric coated with Pu white glue coating has a richer feel, more elasticity, and better fastness.

PA silver glue coating

This coating refers to a layer of silver glue on the surface of the fabric so that the fabric has the function of shading and radiation protection, which is generally used in curtains, tents, and clothing.

PU silver glue coating

The basic function of PU silver glue coating is similar to that of PA silver glue coating. However, PU silver-coated fabric has better elasticity and fastness. For fabrics requiring high water pressure, such as tents, PU silver-coated fabric is better than PA silver-coated fabric.

Pearlescent coating

Pearlescent coating especially refers to the pearl-like luster of the fabric surface by coating. There are silver white and colorful ones. This kind of coating is widely used in garments. There are also PA pearlescent and PU pearlescent, PU pearlescent is more flat and bright than PA pearlescent.

Oil Gloss Coating

Coated with an oil gloss coating, the surface of the fabric is smooth and shiny. This coating is generally applicable to tablecloths.

Silicone high elasticity coating

It is also called paper feel coating. The thin cotton fabric applied with this coating is very suitable for shirt fabric, brittle and elastic, with strong resilience and anti-wrinkle. The thick fabric with this coating has good elasticity and good fastness.

Leather film coating

By calendering and coating the surface of the fabric, a leather film is formed on the surface of the fabric. The general leather film surface is made into the front of the garment, with the style of leather clothing. There are matte and light leather films. By adding colors to the film, a series of the colored film are available.

Flame retardant coating

The fabric has a flame retardant effect by dipping and rolling or coating treatment. And it can be painted in color or silver on the surface of the fabric. It is generally used on curtains, tents, clothing, and so on.

Teflon three anti-treatment

By treating the fabric with DuPont Teflon, the fabric has the function of being water-proof, oil-proof, and dirt-proof.

Anti-UV coating

Through the anti-UV treatment of the fabric, the fabric has the function of anti-UV, that is, the ability to prevent UV penetration.

There are also special coatings for cotton cloth, such as cotton cloth scraping coating, paper feeling coating, washing old coating, hidden grain coating, oil wax coating, color film coating, and so on.